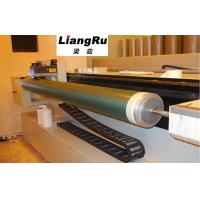

Rotary Nickel Screen For Textile Dyeing Machinery Spare Pats

Manufactures

Our nickel screen,with variety spectifications and good

tanacity,can be repeatly used for several times.

1. Circumference: 640mm, 725mm,819mm, 914mm1018mm,1206mm,1450mm and

1680mm.

2. Mesh: 25-195 mesh

3. Length: 1410-1980mm

4. high open area

5. Suitable for printing on cloth and other fibers in textile

industries and wallpaper printing industries

Textile Machinery Spare Parts Screen Specification:

| Repeat(MM) | 640 725 819 914 1018 1206 1450 1680 |

| Mesh | Thickness(μm) | Open Area(%) | Hole Diameter |

| 125 | 100-105 | 14-16 | 79 |

Not only does this approach reduce printing times, but it also

removes the floodbar as a variable from the printing process.As

previously noted, the flooding and printing action on a rotary

system is all part of the same continuous motion, and separate

strokes for these functions are not required.

Users simply thread the desired material into a rotary machine from

a reel at one end, and the machine continues to pull more material

through as needed.Material handling Because rotary presses work

with web-fed materials, they eliminate the need to feed substrates

into the press piece by piece, as is common with flatbed units.

Specifications

bear high temperature

Excellent toughness & elasticity,

be used for 5~7 times repeatedly,

saving dyestuff,

The virtues of rotary screen printing are most apparent when the

process is compared to traditional flat screen printing.

printing is a two-step process that involves a pass over the screen

by the floodbar to fill mesh openings with ink, The situation is a

little different with flatbed presses. On a flatbed press, followed

by a squeegee pass to bring the stencil and substrate into contact

for ink transfer.

Rotary vs. flat screen printing

Delivery time: within 15 to 25 days

Package: plywood cases or as you required

Rotary screen printing: